Group Members:

Julia Balulis: Lafayette College (Class of 2026)- Mechanical Engineering Major

Paul Hillenmeyer: Lafayette College (Class of 2026)- Undecided Major

Robert Neumeyer: Lafayette College (Class of 2026)- Mechanical Engineering Major

Steven Pang: Lafayette College (Class of 2026)- Electrical and Computer Engineering Major

Noah Schnipper: Lafayette College (Class of 2026)- Engineering Studies Major

The Engineering Design Process:

The Problem Space (Discover/Define):

1. What is the problem you chose to solve?

The problem that we chose to solve is the inefficiency of stocking shelves by employees in a grocery store. Specifically, there is not an accurate inventory of the products on the shelves due to items being misplaced or stolen and the shelves being unorganized. This leads to the time-consuming process of workers checking the shelves to maintain an accurate online inventory. Furthermore, the procedure for putting items on the shelves from large, store-wide shipments is tedious and continuous. Grocery store shelf stockers typically stow some quantity of products in a shopping cart and walk around the store placing them on the shelves, without having a map of where each product is located. Despite seeming like a rather simple, mundane procedure, the intricacies of shelf stocking present complex, system-wide issues that don’t have easy solutions.

2. How did you identify this problem?

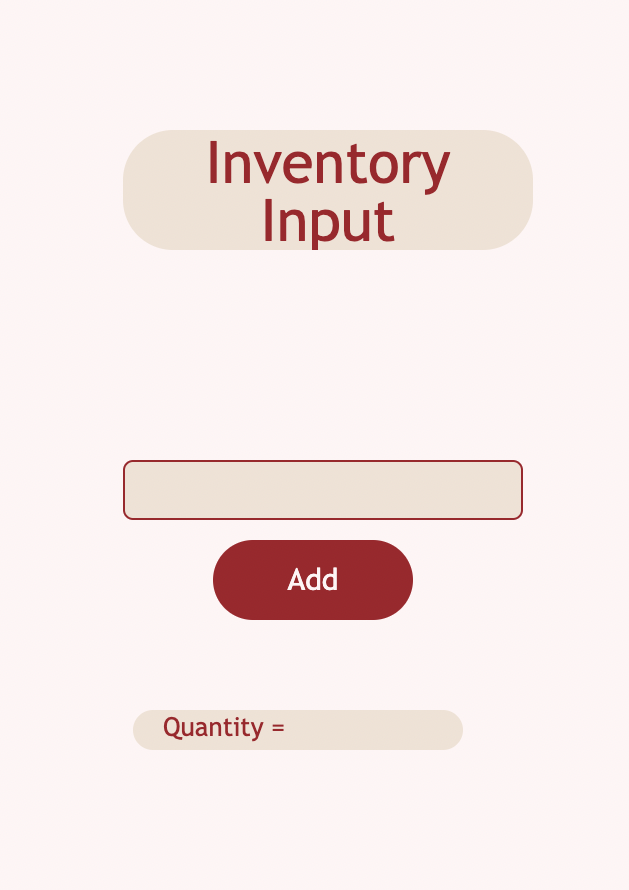

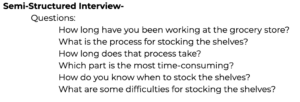

We were able to identify this problem by talking to shelf stockers at the Giant supermarket through a semi-structured interview (Figure 2). Posing follow-up questions to guide the conversations was useful to allow the employees to share more specific concerns and to interject more passion into their answers. Learning about the process of stocking shelves, including how the products arrive at the store, how they are transported to the floor, and how they are put onto the shelves, informed our problem definition. These interviews were invaluable because the potential users’ needs deviated from our own experience. As a group, we had little knowledge of the procedures and problems faced in a grocery store setting from the employees’ perspective. The industrial processes and organizational responsibilities in order to stock the shelves are complex and unseen by the casual customer. Many of our predictions about how the process worked were mostly incorrect because we assumed that the process would be more streamlined and have multiple checks. For example, I (Julia) assumed that the products would arrive from the company warehouse to the store organized by product type, aisle, or serial number, all of which was incorrect. Additionally, I (Noah) assumed that each stocked product or box had to be marked in the online inventory system, which was also incorrect. The deviation of the grocery employees’ needs regarding the shelf stocking process from our perception of their needs created empathy and crystallized the problems that can be fixed to improve their workplace.

Figure 2: Semi-Structured Interview Questions (Discover)

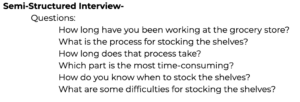

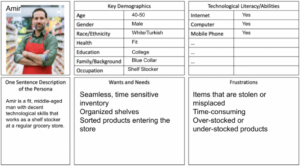

3. Who are you designing for?

We are designing a solution to ease the jobs of shelf stockers in large supermarkets (Figure 3). These employees are presumed to be fit and have relatively good technological literacy. Our psychological distance from these stakeholders led to increased interest and focus on user research. Having very little previous knowledge of the job of shelf stockers made it more necessary and interesting to do user research. Furthermore, gaining information about the difficulty and monotony of their job created empathy and reinforced the importance of developing a better solution to assist them. Our lack of familiarity with the workplace of shelf stockers and the problems they encounter is one of the reasons that we chose to design for shelf stockers. By having a fresh perspective on their problems, we believe that we could develop a dynamic, novel solution.

Figure 3: Shelf Stocker Persona (Define)

4. Who are you not designing for? What measures did you take for intentional inclusivity – why/why not?

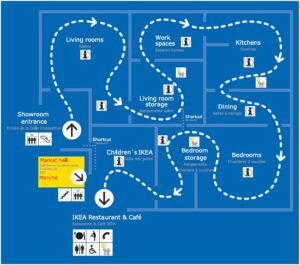

We are not designing for employees of the store that are not shelf stockers (Figure 4). We made sure to design a solution that would be simple and easy to use for people with varying levels of education. Furthermore, we are making sure to include many of the principles of universal design, such as Principle 3 (Simple and Intuitive Use), Principle 5 (Tolerance for Error), Principle 6 (Low Physical Effort), and Principle 7 (Size and Space for Approach and Use). Applying these principles will improve the accessibility of the design and allow most people with visual or physical disabilities to work as shelf stockers.

Figure 4: Shelf Stocker Antipersona (Define)

The Solution Space (Develop/Deliver):

5. What is your final solution and what does it look like?

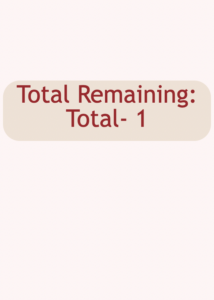

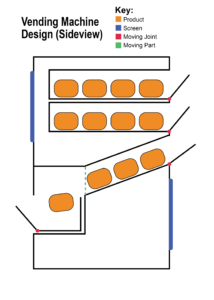

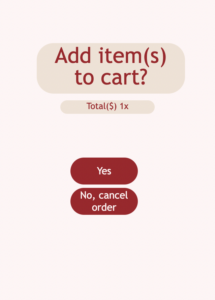

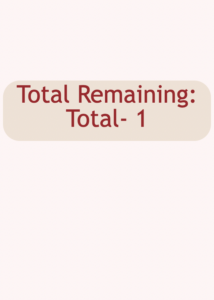

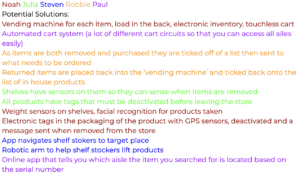

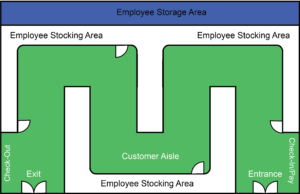

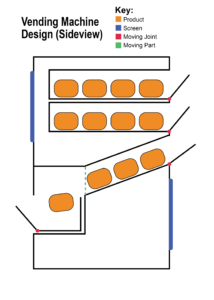

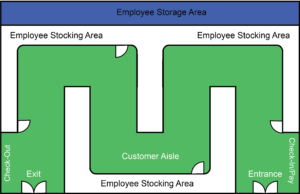

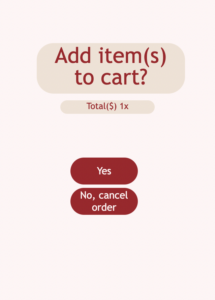

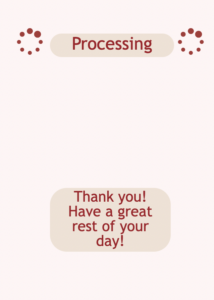

Our goal is to assist the employees working as shelf stockers by organizing products in module vending machines that contain one product each. The purpose of the ‘vending machine’ design is to improve the ease of shelf stocking (in the back of the machine), to have an accurate and time-sensitive inventory, to organize the location of each product, and to restrict the customer from disrupting the stocked ‘shelves’ (Figure 10). The machine will be used by the customer via a touch screen, which will have a user interface to send the quantity of product requested to the customer’s shopping cart (in the front of the machine) (Figure 12). As the customers use the machine via their fingerprint, the machine will log the number of products taken out of the inventory and will charge the previously-entered, associated money account. The employees will use a touchscreen on the back of the machine to check the current inventory and to log ‘stocking the shelves’ (Figure 13). The online centralized system will also be connected to the machines in order to order refills of specific products and to adjust the number of each product in scheduled store-wide orders. Because only employees will have access to the back of the machines and the customers will have access to the front of the machines, the layout of the store will be redesigned. To improve the efficiency of placing products in the machines, there will be a miniature version of the store layout in the back of the store as a staging area for the employees. Also, a map of the store with the location of the machine for each product will be available physically and online.

Figure 10: Vending Machine Design Sideview (Deliver)

Figure 12: Customer User Interface Screens (Deliver)

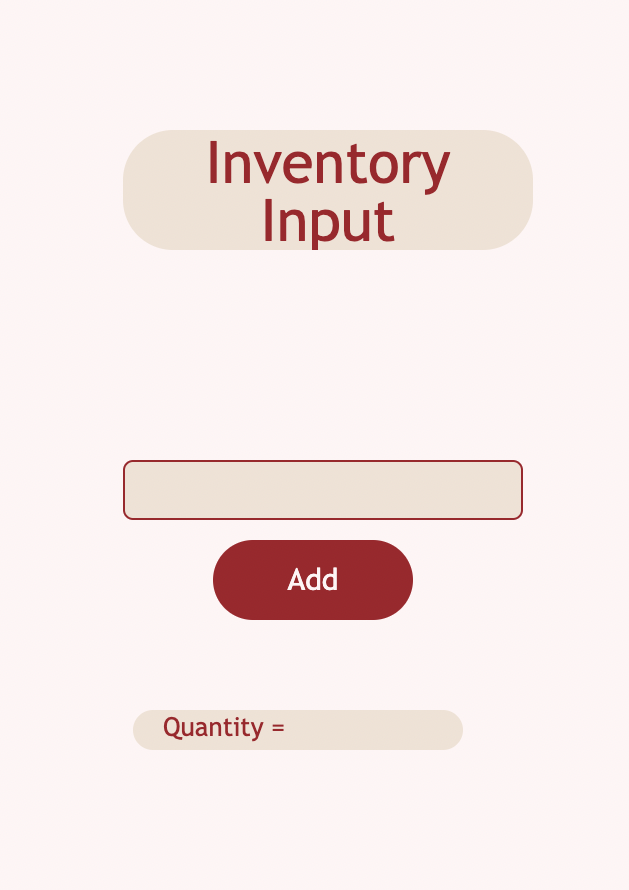

Figure 13: Employee User Interface Screen (Deliver)

6. How did you arrive at your final solution? What methods did you use to generate, select, and build solutions?

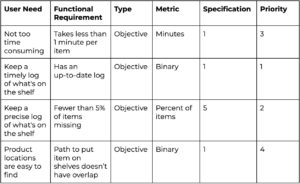

We arrived at our final solution by doing a thorough job during the problem exploration and problem definition phases. By having the specific problems that we wanted to solve, we were able to find a solution that remedied all of those problems, based on a concept we see in the world. In this case, our inspiration for the design came from vending machines. The module, self-contained nature of vending machines make them desirable to minimize customers’ contact with the products and keep track of inventory. The layout of the store took inspiration from the layout of IKEA (Figure 9). We used numerous methods to generate solutions and to guide prototyping, including a Pugh Chart (Figure 5), a silent ‘gallery’ brainstorm (Figure 6), and a prototype planner.

Figure 5: Pugh Chart (Define)

Figure 6: Silent Gallery Brainstorm (Define)

Figure 9: IKEA Store Layout Topview (Develop)

7. How do you know that this solution works?

To ensure our solution worked, our group designed and built a miniature physical prototype, enabling us the ability to test our design. We used a cardboard and duct tape functional model to test the feasibility and usability of the prototype (Figures 7/8). To receive feedback from individuals outside of our project group, we asked our classmates to test our physical prototype and our user interface (Figures 12/13), which generated useful feedback. Based on the first round of prototype testing, we simplified the design concept (allowing customers to access the products easier) and tweaked the user interface (switching the location of buttons). The altered designs (Figures 10/11) proved to be more successful in our second round of prototype testing.

Figure 7: Cardboard/Duct Tape Prototype Front (Develop)

Figure 8: Cardboard/Duct Tape Prototype Back (Develop)

Figure 10: Vending Machine Design Sideview (Deliver)

(See Above)

Figure 11: Grocery Store Layout Topview (Deliver)

Figure 12: Customer User Interface Screens (Deliver)

(See Above)

Figure 13: Employee User Interface Screen (Deliver)

(See Above)

Reflection on the Engineering Design Process:

8. What did your team do well in your design process?

Our group did well in the problem discovery and solution specification phases of the engineering design process and worked together successfully. Since none of us had knowledge of the shelf-stocking process nor problems that shelf-stockers encounter, we did effective, in-depth research to identify potential problems. On the other hand, our solution involves system-wide changes that address all of the problems that we identified while maintaining the general structure of the grocery store. The additive nature of the design makes the solution potentially usable to retrofit existing grocery stores, following the creation of more advanced hardware and software designs. Finally, our group did well in maintaining communication and letting each other know when we found flaws in our design. We were able to accept constructive criticism and use the criticism in order to improve our design.

9. What were some of the challenges that you faced as a team when designing?

During the engineering design process, we had difficulty choosing whether to create the design project for customers or employees. Throughout the design process, this problem continued to arise, even in the final days of building and testing. In the end, our final design tailors to employees; however, the design also simplifies the grocery store shopping procedure for customers, especially through the store layout map. The conflicting goals for the design made the phases of ideation and presenting the prototype more complicated and convoluted than they should have been.

10. What changes/improvements would you make in your design process in the future?

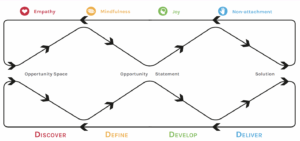

Our group would have liked more time on the deliver phase of the design process in the future. The quick turnaround time for developing a design, prototyping, and testing led to a finalized design that is somewhat low-fi, though effective in concept. We would have liked more time to alter the prototype, along with technical tools to develop a more high-fidelity prototype, such as computer-aided design software and more secure programming software. However, our overall process of engineering design using the double-diamond model led to an effective and well-developed final design.

Figures:

Figure 1: Double Diamond Design Process

Figure 2: Semi-Structured Interview Questions (Discover)

Figure 3: Shelf Stocker Persona (Define)

Figure 4: Shelf Stocker Antipersona (Define)

Figure 5: Pugh Chart (Define)

Figure 6: Silent Gallery Brainstorm (Define)

Figure 7: Cardboard/Duct Tape Prototype Front (Develop)

Figure 8: Cardboard/Duct Tape Prototype Back (Develop)

Figure 9: IKEA Store Layout Topview (Develop)

Figure 10: Vending Machine Design Sideview (Deliver)

Figure 11: Grocery Store Layout Topview (Deliver)

Figure 12: Customer User Interface Screens (Deliver)

Figure 13: Employee User Interface Screen (Deliver)